News

Meet with us @

Posidonia 2018

STAND 3340

Tags

- CBM 3

- Resonance 2

- Ships 2

- Education 1

- Vibration Analysis 1

APPROVED

SERVICE SUPPLIERS

IR Thermography

- Details

- Category: News

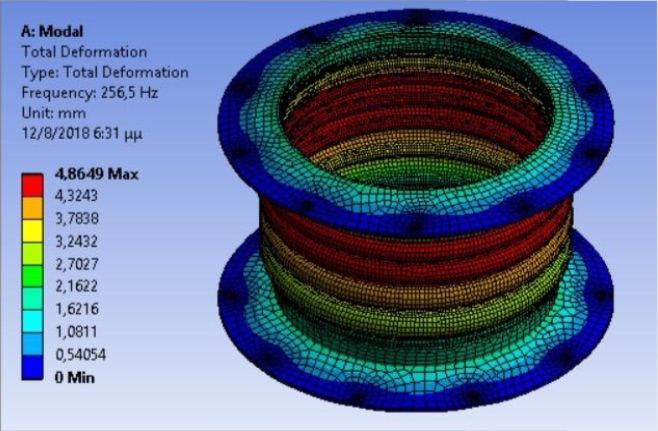

Finite Element Modelling and Dynamic Analysis

of Vibration Related Structure Failures

- Details

- Category: News

Condition based maintenance (CBM) philosophy uses a variety of monitoring techniques in order to assess the necessity of repair actions prior to a system’s defect occurring. The methods that can be used for machinery evaluation include techniques such as vibration analysis, thermography, acoustic emission, oil and wear particle analysis. The aforementioned techniques are a potential asset of any maintenance personnel that aims to reduce the life cycle cost of industrial equipment. The aim of this paper is to present an example of the application of vibration analysis as an efficient, cost-effective and reliable maintenance technique for motor bearings fault diagnosis.

- Details

- Category: News

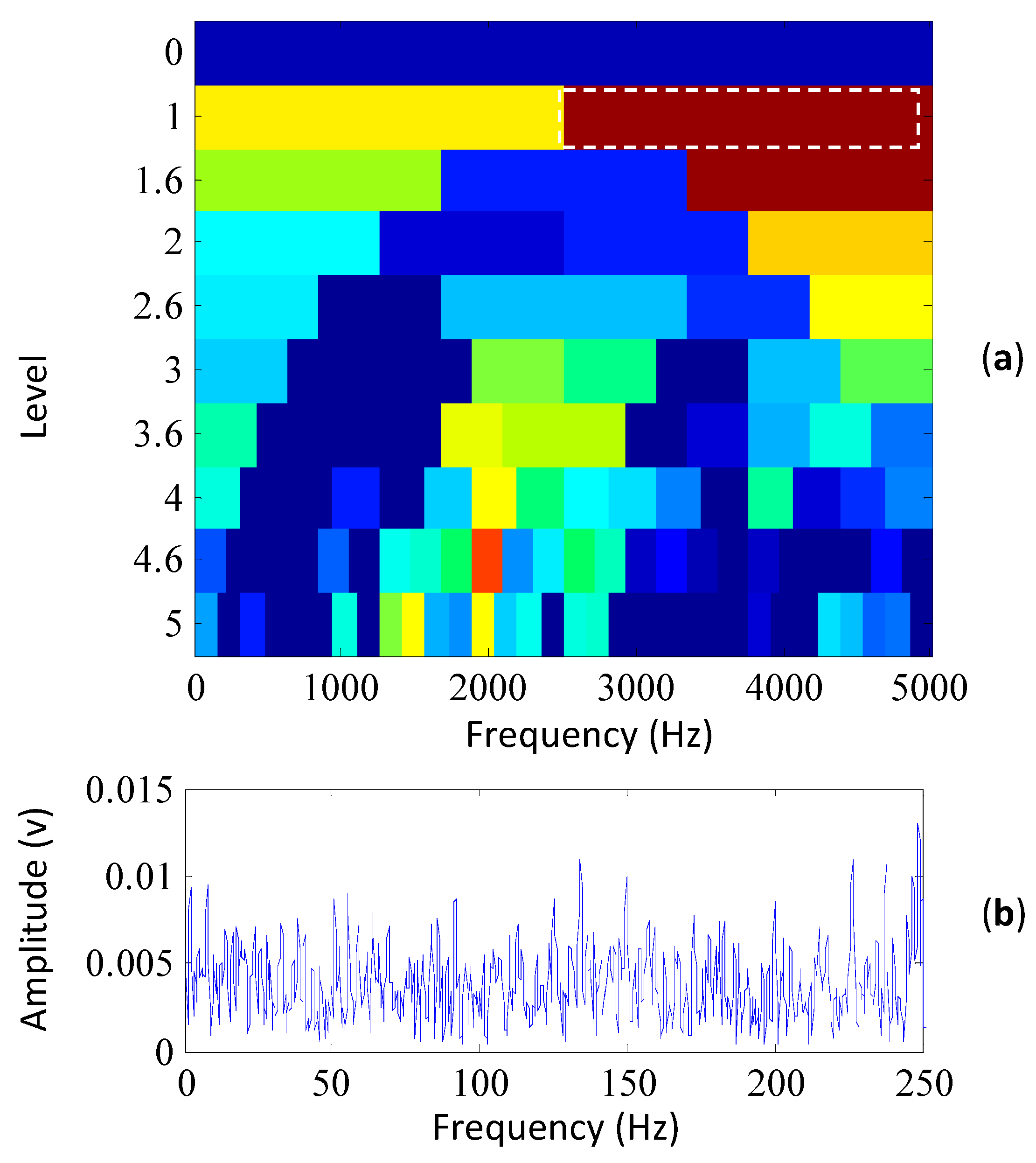

Propeller “singing” phenomenon is defined as the resonance between the natural frequency of the propeller blade tip and the vortex shedding frequency at trailing edge of the blade. Propeller “singing” phenomenon as a result of the above resonance of propeller blade tip, creates a very intensive levels of radiated noise. In general the singing phenomenon occurs when the frequency of the response related to the vibratory amplitude of the blade coincides with vortex shedding frequencies of trailing edge of some blade sections.

© 2026 - FNT at Sea Services Ltd | All Rights Reserved / Website Developed by GTW