Maximizing the value of your collected data

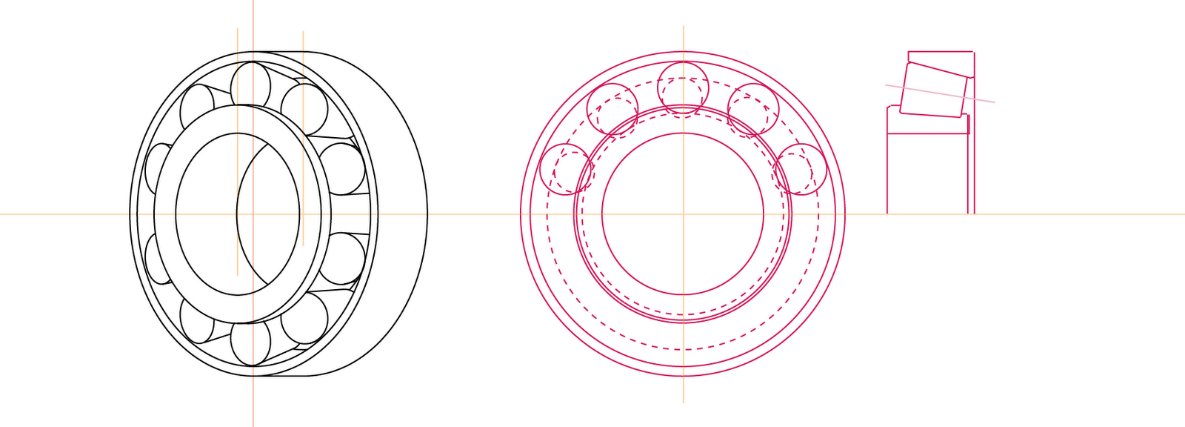

The nature of the vibration signal to react in changes of rotating equipment’s condition makes it a useful and effective mean for machinery monitoring. Furthermore it can precisely locate defective components in rotating machines such as bearings, gears, impeller blades etc. Even if fault indications may be covered by noise, there are various and efficient digital signal processing techniques that are applied in vibration analysis.

In FNT at Sea Services Ltd we devote a great part of our R&D efforts to develop advance signal processing algorithms that enable us to overcome challenges and “see through data smog” in order to identify bearing faults at earliest stages of defect. In the frame of that effort an algorithm for bearing fault detection, based on Antoni J. and Randall R.B. proposal as presented at “The Spectral Kurtosis: Application to the Vibratory Surveillance and Diagnostics of Rotating Machines” has been developed, tested and presented in a white paper issued by FNT. In this paper FNT elaborates and tests the effectiveness of the parameters spectral kurtosis and kurtogram as tools for vibration signal analysis for bearing fault identification at early defect stage.

The results proofs that spectral kurtosis and kurtogram is an effective and reliable vibration analysis tool, and highly recommended for bearing condition evaluation.

Download the paper from here.